Monitoring of

a heat exchanger

a heat exchanger

Quality control of product cooling and process stability

Система помогает оперативно реагировать на критические изменения в системе и сокращать затраты на производство продукции

Monitoring allows

rationally plan and save resources

monitor the performance of process equipment

control and observe the entire technological process of production

maintain the quality of the product

control the implementation by an operator of recommendations and instructions from an equipment manufacturer, at each individual section of a process

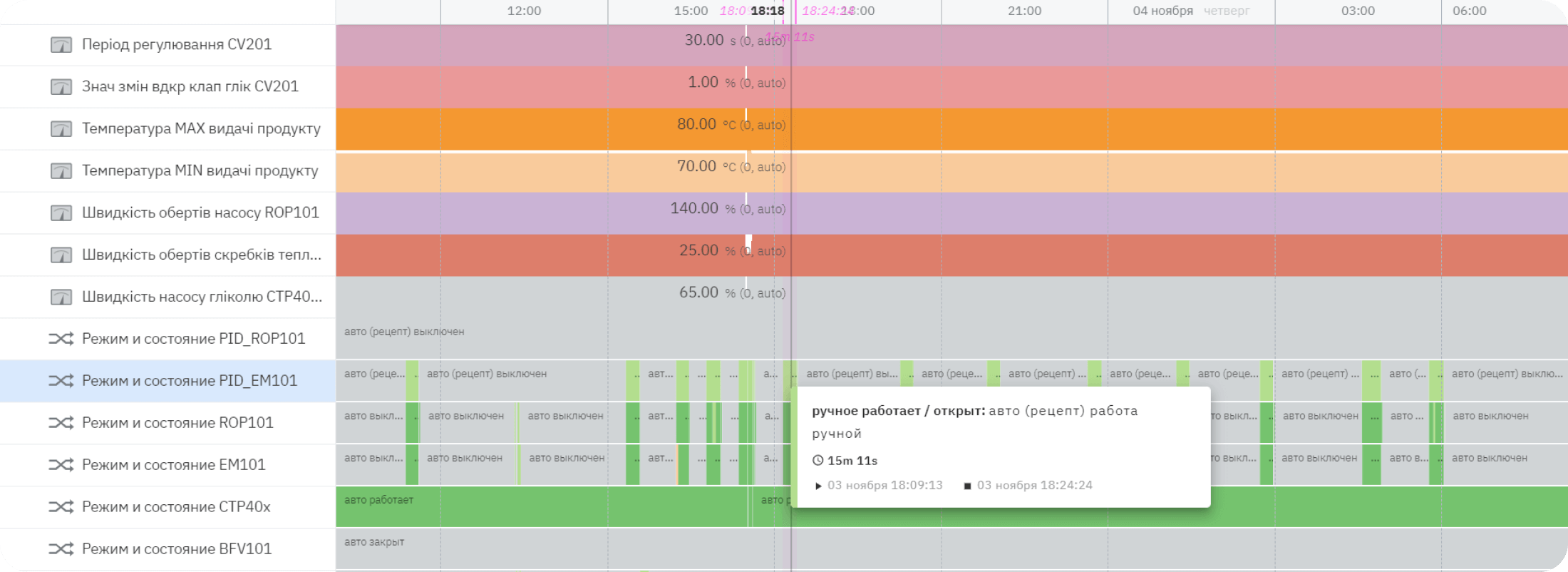

Heat exchanger monitoring includes the following data

Product temperature

Glycol supply temperature

Electricity consumption

Operation status of each valve

Control valve, how much percent is it open

Other

All data during the monitoring of the heat exchanger are sent to QiVisor WEB

The control of the cooling process makes it possible to produce consistently high quality products.

For example, in the production of food products (sauce, mayonnaise, adjika, etc.), cooling equipment - heat exchanger is used. Refrigeration equipment is designed to cool just cooked finished product, then the product is packaged in containers.

The heat exchanger cools the product by circulating glycol through the heat exchanger jackets.

The volume of glycol supplied to the heat exchanger is dosed by a control valve. The glycol circulation speed is set by a centrifugal pump with frequency converter.

In this case, products need to be produced in a strictly limited time, which requires fine-tuning of the heat exchange process, which can be helped by monitoring this process to collect parameters during real production, which will give the opportunity to "polish" the control programs of the heat exchange process.

Feel free to ask us any questions and take your production to the next level!

Want to know more?

© All Rights Reserved.

META SYSTEMS LLC

META SYSTEMS LLC