For whom?

What are we selling?

The QiVisor web application is a system for automatic accounting of utilities consumption.

Online accounting of utilities, as well as with the ability to generate a monthly report and send it by email

Electricity accounting

Water accounting (cold / hot)

Advantages

The data is available from any web browser on any device:

Display of graphs of histograms for all parameters that will be set

Export of reports in Excel spreadsheet format

The simplicity of system installation

System expandability

Control elements management

Display of graphs of histograms for all parameters that will be set

Sending e-mail notifications to selected e-mail addresses

The example of an implementation

The client's task was to take data from sensors and send them to e-mail. The client had installed the following sensors:

Electricity counter Mercury 234 ART - 03P (pulse output)

VSGd-15 hot water counter (pulse output)

VSKhd-15 cold water counter (pulse output)

Proposed solutions

Based on the received information, we offered to install a monitoring unit with two options to choose from:

Option 1 (low-cost)

Option 2 (optimal)

The basis of the monitoring unit

A microcontroller that belongs to the IoT class

An industrial controller based on a Raspberry Pi single-board computer that runs on the Linux operating system

The number of input signals

4

8

Expansion possibility

Possibility of the e-mail distribution

Advantages

- Autonomy of work not less than 24 hours.

- Control of three consumers, which are controlled by contactors or solid-state relays.

- Support for remote connection to the controller.

- Possibility of expanding the functionality of the system to control a large number of consumers using the RS-485 module.

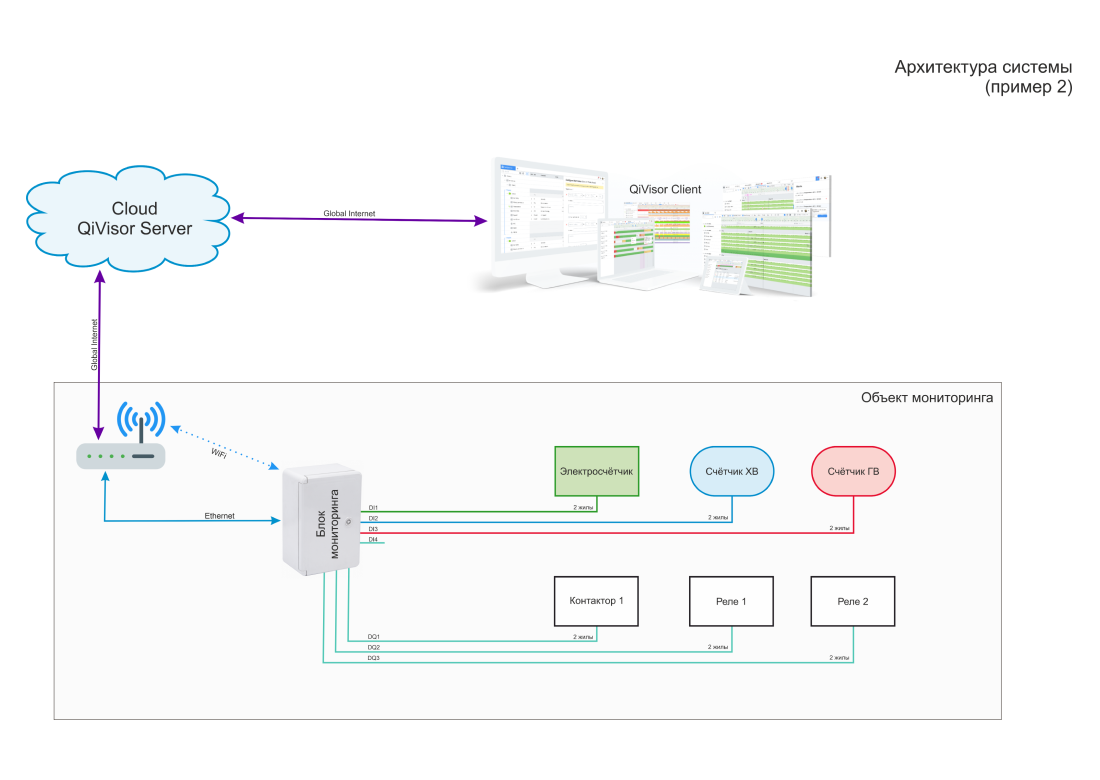

System architecture No. 1

The device has a built-in rechargeable battery that allows it to work in the absence of a constant power supply (at least 24 hours). The device has a hardware counter of impulses for each input signal, which means from each counter. The microcontroller processes input signals and transmits the received data to the cloud server. Also, this controller implements email distribution to the specified e-mail addresses.

autonomy, the ability to control 3 consumers, which are controlled through contactors or solid-state relays (turning on / off lights, air conditioners, power outlets, etc.).

Advantages:

The monitoring unit is based on a microcontroller, which has 4 input signals (from counters) and 3 output signals (dry contact) WITHOUT EXPANSION POSSIBILITY. This device belongs to the IoT (Internet Of Things) class.

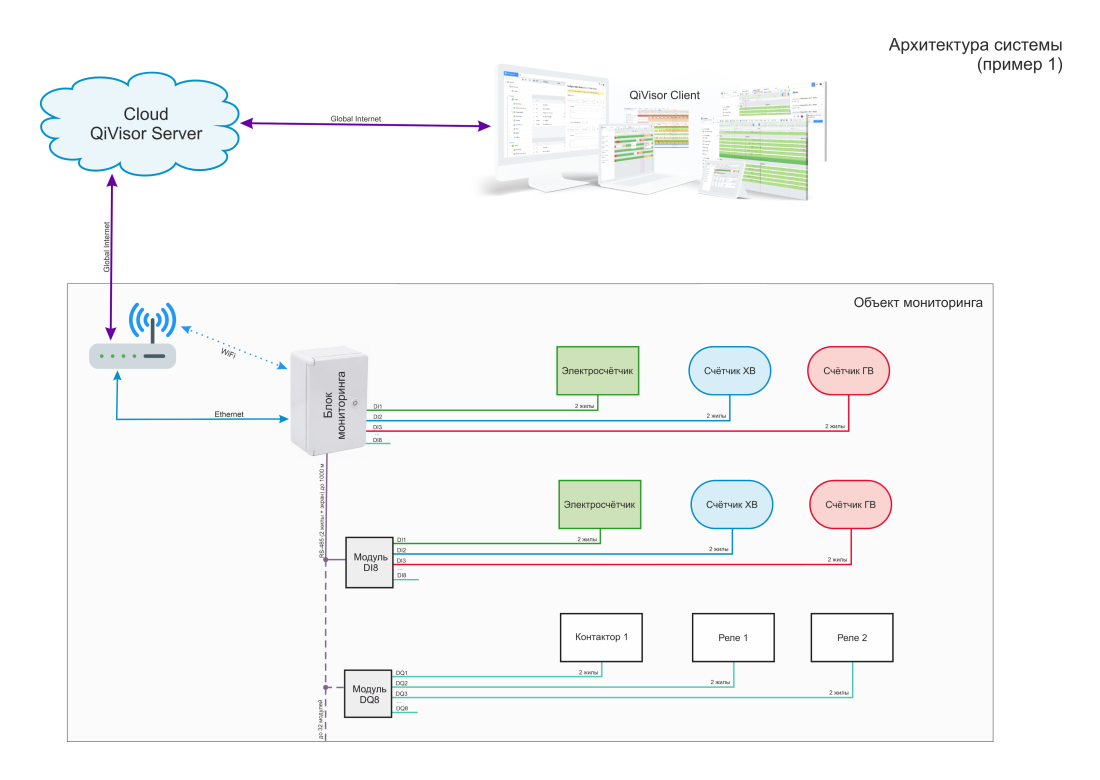

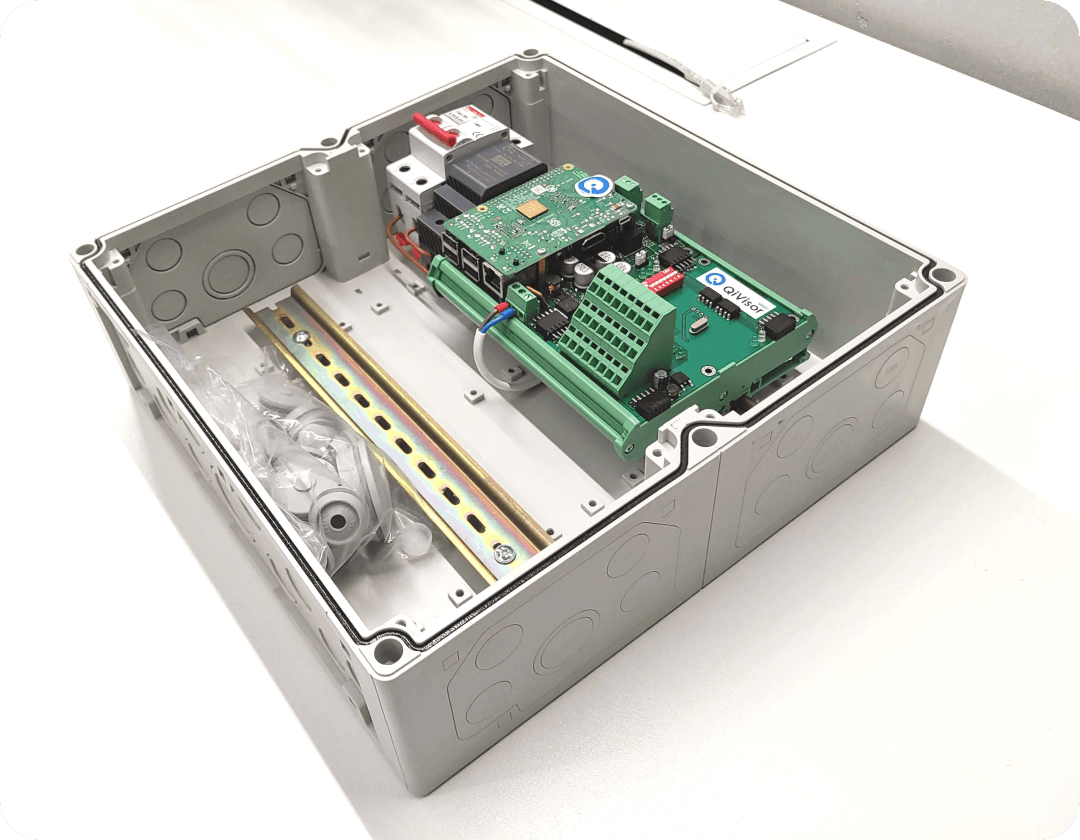

System architecture No. 2

The controller, together with plug-ins, processes signals and sends data to the cloud server. Also, this controller implements email distribution to the specified e-mail addresses with the ability to customize notification rules.

The hardware capabilities of the controller, using the industrial interface RS-485, allow you to expand the functionality of the system by connecting an analog input or discrete output module, which allows you to CONTROL A LARGE NUMBER OF CONSUMERS.

Advantages:

The monitoring unit is based on an industrial controller based on a single-board computer Raspberry Pi, which runs on the Linux operating system. The controller is completed with a module of input discrete signals (8 inputs) with the possibility of expansion. This module has a hardware counter of impulses for each input. MAXIMUM NUMBER OF CONNECTED MODULES 32 PCS.

The service includes a license, support and data storage on a cloud server. The number of users and devices is not limited (within the license).

Software — cloud-based WEB-application "QiVisor" is provided as a service and does not require the installation of a computer or server, additional equipment, software, and its support and updates.

Part of work by the customer

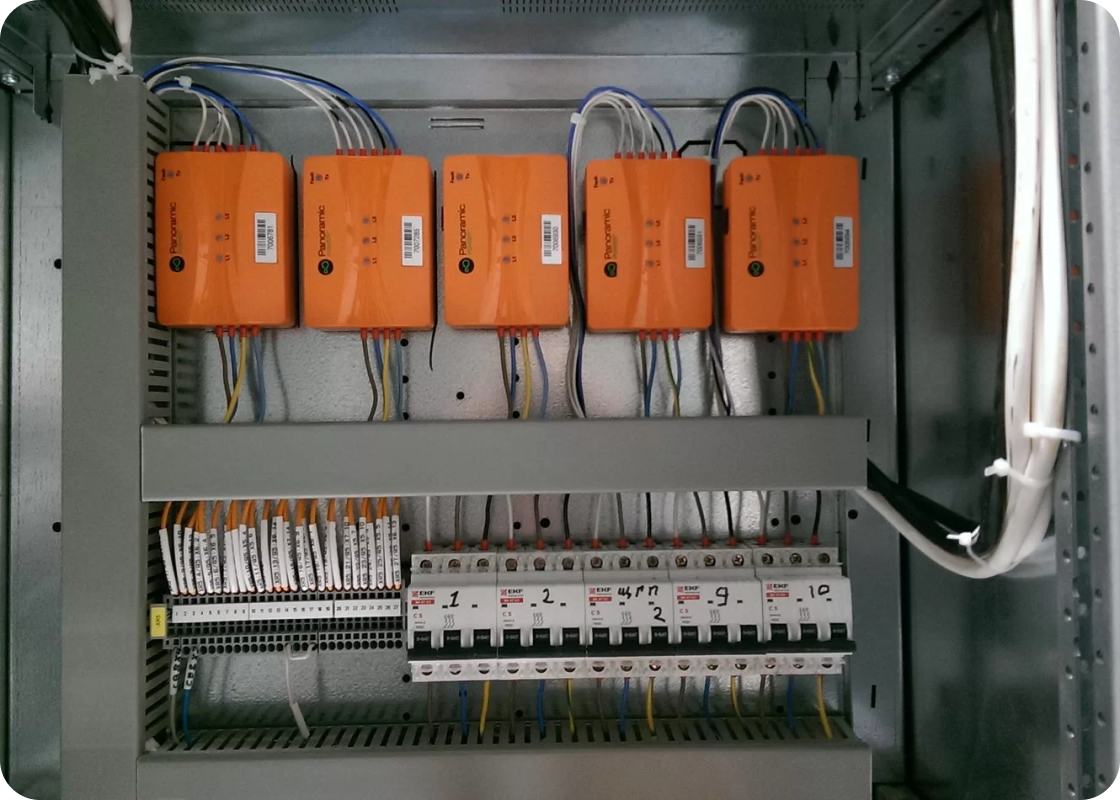

Installation of the proposed system is easy. So, the Customer did these works on his own with our remote support. The client independently installed electrical cabinets and connected cables for collecting data from counters at the facility.

Feel free to ask us any questions and take your production to the next level!

Want to know more?

© All Rights Reserved.

META SYSTEMS LLC

META SYSTEMS LLC