Automatic fixation of production data and their export to an Excel report.

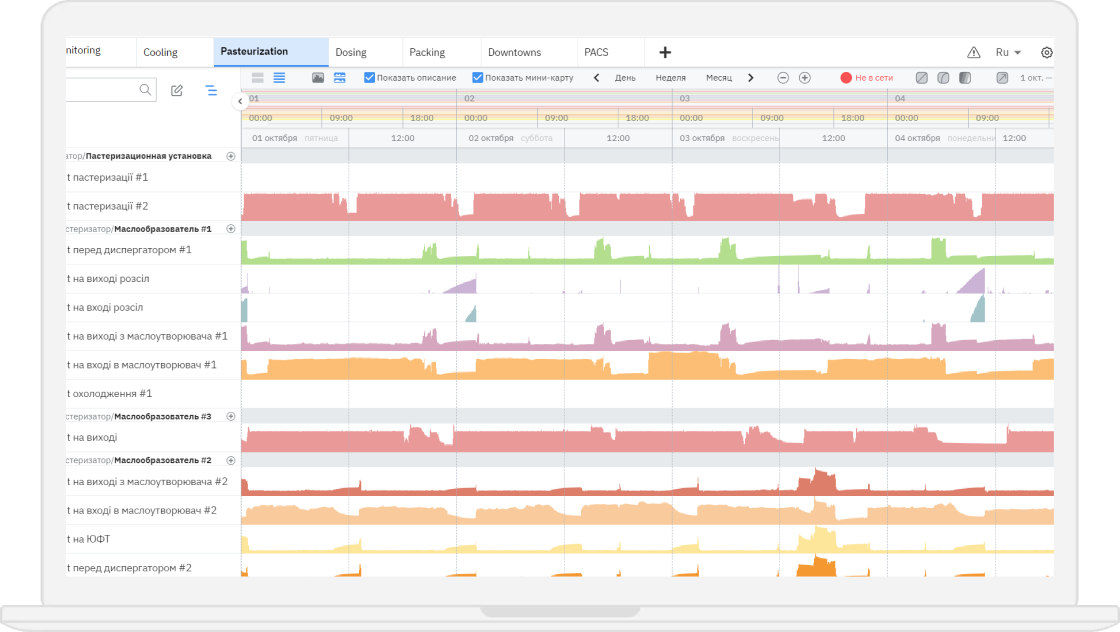

QiVisor allows you to monitor all temperature parameters in one window.

What is it needed for?

Checking the registrations of manual journals based on the actual registrations of the sensors

Control of the pasteurization process and butter dosing in one window

Increasing the speed of analysis of the arisen technological problems in production

Improving product quality

Reducing the number of product defects

Increasing the speed of transition from one process to another

Instant notifications of equipment failure

Implementation from 2 to 4 weeks

What are we selling?

QiVisor web application for online monitoring of product quality.

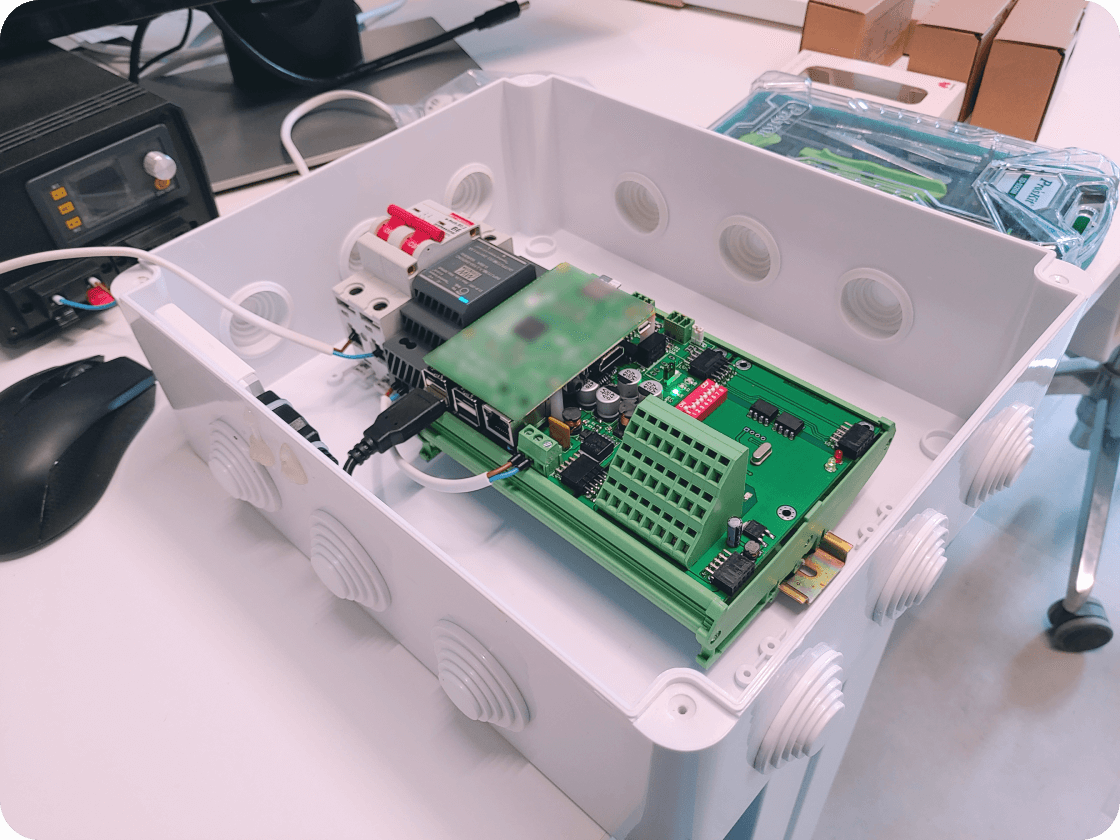

We use your controller or we will select ours

Any point of control

We connect to installed measuring devices or select and install new sensors

The example of equipment that can be monitored with QiVisor in a butter dairy

Client tasks:

The example from the industry

Analysis of the work of production cycles to improve the speed of production and reduce the number of product defects

Comparison of indications to identify the causes of equipment breakdown, quality violations

Monitoring indicators from different types of equipment with data output on one screen

The QiVisor system monitors temperature sensors at the Tulchinsky Butter and Cheese Factory.

We offered a solution for monitoring, that is based on a controller of our own design. We sent the kit by post with instructions and provided video instructions on how to use the program.

Solution

After the implementation of QiVisor, everything has become much easier — all indicators can be checked at any time and on any device."

Previously, the factory was guided by manual records in checklists: a foreman or operator recorded technological parameters every 20-30 minutes. With this method of collecting information, the human factor plays a key role — sometimes an employee may not have time to record indicators and gaps appear in the records. And in a case of a discrepancy in the quality of the finished product, it is impossible to examine the root causes of this.

"The factory employees were able to independently connect the equipment and launch QiVisor in 1 day.

Feedback

Feel free to ask us any questions and take your production to the next level!

Want to know more?

© All Rights Reserved.

META SYSTEMS LLC

META SYSTEMS LLC