Data collection and transmission via ModBus

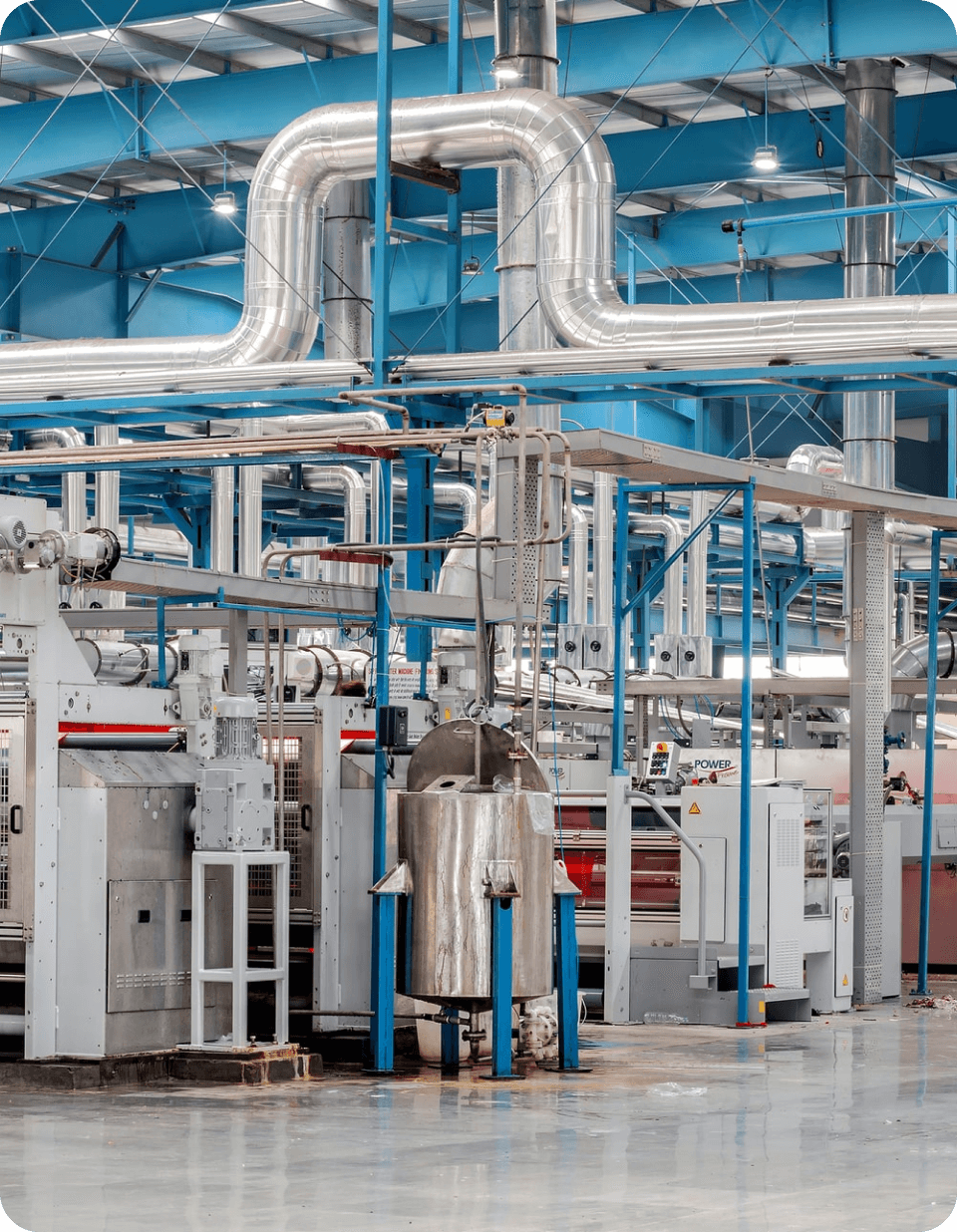

Monitoring system for Refrigeration Equipment

What do we offer?

Energy consumption monitoring to analyze the annual efficiency of equipment operation. Cost savings for opening new stores, warehouses.

Supermarkets, large logistics warehouses, refrigerator warehouses monitor the costs of resource consumption and equipment usage.

What is it for?

The capabilities of the system allow:

make a decision on the discreteness of the compressors (1 large or 5 smaller);

collect and transmit data using the Modbus protocol.

analyze the full range of information for service departments and optimize energy consumption and system performance

analyze equipment downtime;

find out how efficiently the equipment is operating;

receive alarms / notifications about accidents and malfunctions

find out the average annual efficiency;

find out annual efficiency;

The speed of implementation and simplicity of use of the program will be a pleasant bonus. Any user can easily figure out how to use the system from the first login to the application.

QiVisor provides a full range of information for a comprehensive analysis of equipment by service departments and optimization of energy consumption and system operation.

Remote monitoring opens up endless possibilities for planning and analyzing the work of engineers, power engineers, instrumental technician specialists and process engineers.

We can visualize any data that is collected on your controller in the monitoring system on graphs. Moreover, it can be displayed in the online HMI panel.

The advantage of the QiVisor Web monitoring system is the ability to view historical data for any period of time and from any place: on a phone, tablet, laptop.

The advantages

Refrigeration monitoring usually includes data of:

The controller that manages the refrigeration station sends data to the QiVisor WEB via the Modbus protocol.

Implementation example

other.

flap status;

energy consumption;

temperature;

Disadvantages:

What equipment is monitored:

high price of the license and controller.

For what purpose:

What is monitored:

Danfoss, Carel, Dixel and Eliwell, Siemens.

storefronts, freezer bonnets, freezers, compressor units, freezing equipment, water cooling units and freezing tunnels.

Similar monitoring systems are offered by: Danfoss, Carel.

Similar monitoring systems are offered by: Danfoss, Carel.

– remote control of equipment operation;

– timely alarm reaction, temperature data storing;

– early detection of the signs of equipment malfunction in order to avoid compressor failure and increase its service life, accurate maintenance of the refrigerant temperature.

– timely alarm reaction, temperature data storing;

– early detection of the signs of equipment malfunction in order to avoid compressor failure and increase its service life, accurate maintenance of the refrigerant temperature.

sudden surges in energy consumption, temperature surges, pressure changes, time and frequency of defrosting the refrigerator.

General information

Controllers that are most often used in this scope:

QiVisor can be integrated with Carel systems.

Carel

QiVisor

Data transfer protocol

BACnet™, ModBus™

ModBus™

Energy consumption control

Real time monitoring

History in graphs

Real-time data in graphs

Reports

Notifications of exceeding the overriding criterion

Equipment management

Set the time for turning on and off street lighting with sunrise and sunset: sets the coordinates of latitude and longitude.

Setting the temperature and on-off by time, day of the week

Effective cooling: turn on the air conditioning system before sunrise using enthalpy calculation

Allows you to set the time when the air conditioning system turns on and for how long it turns on

Web application

Price

From 1559 Euro

From 200 Euro

Feel free to ask us any questions and take your production to the next level!

Want to know more?

© All Rights Reserved.

META SYSTEMS LLC

META SYSTEMS LLC